By DCB Editorial, April 6, 2022

Volvo Autos has manufactured a strategic investment in Bcomp, an progressive Swiss business that develops higher-general performance light-weight components centered on all-natural fibres, via the Volvo Automobiles Tech Fund, its venture capital arm.

To make its products, Bcomp takes advantage of flax fibres, a bio-primarily based material that delivers considerable financial savings in terms of fat, power use and emissions versus typical plastic parts. The substance also allows design and style selections for aesthetic surfaces.

Tthe use of Bcoup’s pure fibre composites will element in Volvo’s up coming technology of pure electric vehicles. Bcomp’s calculations show that in contrast to frequent plastic elements, the natural fibre-based composites are up to 50 for each cent lighter, use up to 70 per cent significantly less plastic and create up to 62 for each cent reduce CO2 emissions.

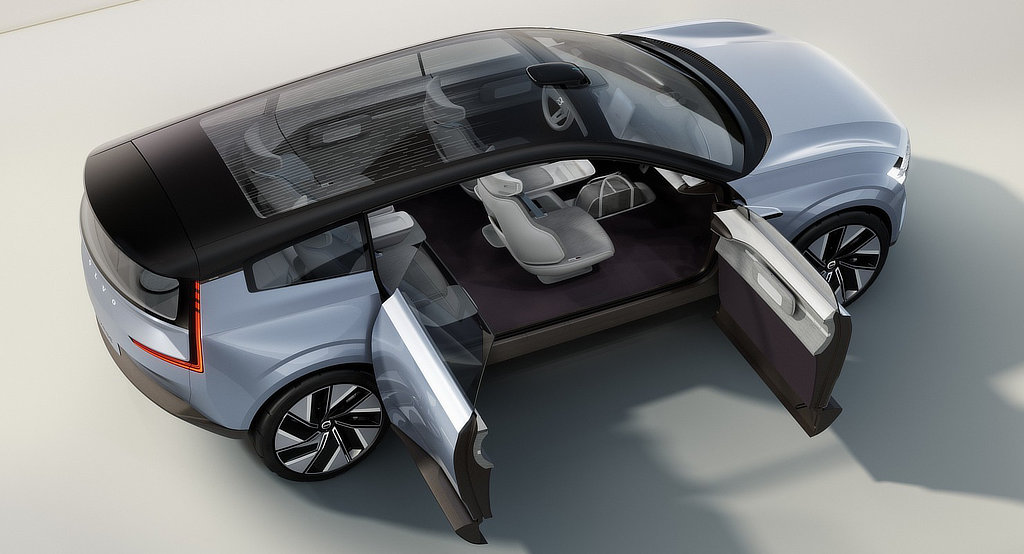

Bcoup’s materials was incorporated into latest Volvo Thought Recharge. This demonstrates the measures Volvo Cars and trucks aims to consider in all spots of pure electrical car or truck progress to lower its cars’ and its overall carbon footprint. The business plans to market only fully electric powered vehicles by 2030 and aims to be a local climate-neutral business enterprise by 2040.

Inside the Volvo Autos Idea Recharge, Volvo Vehicles has made use of a flax composite for the decreased storage locations, the back of the headrests and the footrests. On the exterior of the car or truck, the entrance and rear bumpers as perfectly as the sill mouldings consist of flax composites.

The ambition to frequently lower emissions and develop into weather neutral by 2040 is component of Volvo Cars’ climate action prepare, just one of the most ambitious in the marketplace. By now by 2025, the enterprise aims to lessen lifecycle CO2 emissions for each automobile by 40 per cent compared with 2018.