Table of Contents

Demand from customers for electrical automobiles is definitely escalating at a big clip, and they are widely anticipated to be the principal variety of vehicle in the many years to occur.

On the other hand, they at this time characterize a minuscule share of the overall new auto marketplace, with the huge vast majority of the world’s automotive fleet even now working with an interior-combustion engines – whether or not by by itself or as part of a hybrid arrangement.

This raises the concern of regardless of whether there is nearly anything that can be performed to reduce the emissions and carbon footprint of autos previously on the street now. eFuels are 1 potential reply to this problem.

They’re also possibly a way to continue to keep thirsty, noisy, emotional inside-combustion engines alive in small portions as the globe goes electrical.

What are eFuels and how are they created?

The phrase ‘eFuel’ stands for ‘electrofuel’, with the electro part of this term denoting that electrolysis is an necessary stage in the production of eFuels. eFuels are also frequently known as synthetic fuels.

In limited, eFuels have the likely to be manufactured in a sustainable way, that recaptures atmospheric carbon dioxide through the creation system, supporting to offset any carbon dioxide emissions launched when an eFuel is burned by a car or truck, and allowing for near to web-zero emissions.

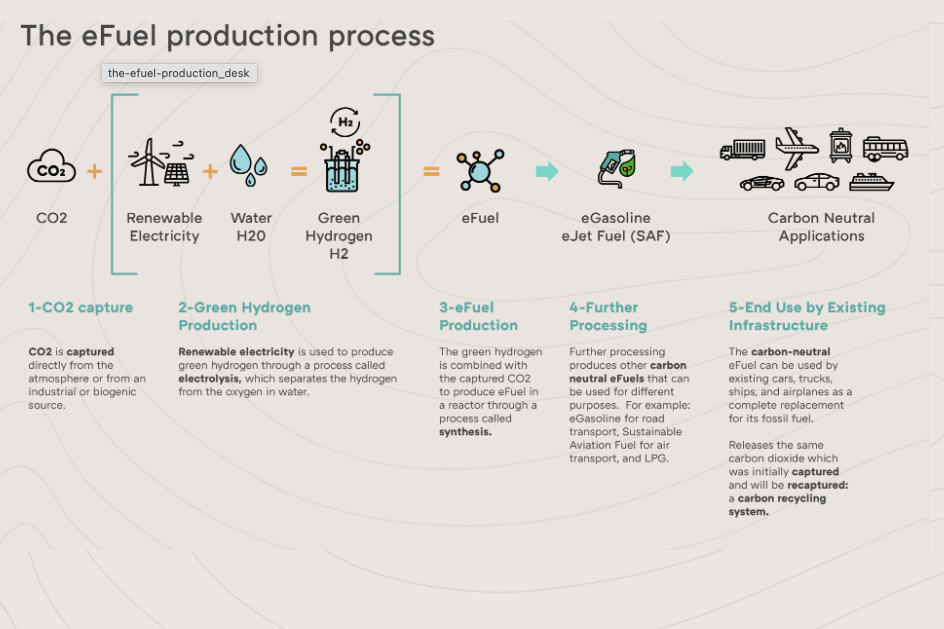

Recapturing this carbon dioxide functions as the very first phase of the eFuel output course of action, with the eFuel company using a variety of procedures to seize CO2 directly from the air, or from other sources in the surroundings.

A independent renewable electrical energy source, these as hydroelectricity or solar power, is utilized to make hydrogen in a sustainable method by powering a procedure acknowledged as electrolysis, whereby an electrical present is applied to independent hydrogen atoms from oxygen in h2o.

Future, this sustainably-generated hydrogen is put together with the formerly recaptured carbon dioxide in a plant, by a method recognized as synthesis, to create eFuel, generally in the sort of methanol.

Methanol in selected circumstances can be utilised specifically to power automobiles, or refined/converted more, this sort of as by way of the methanol-to-gasoline procedure invented by oil big ExxonMobil, to be utilized as a substitute for naturally sourced fossil fuels these types of as petrol and diesel.

What are the potential positive aspects and downsides?

The principal profit of eFuels is that they have a substantially lower general carbon footprint in comparison to the natural way-sourced fossil fuels, with vehicle makers such as Porsche boasting an 85 for every cent reduction in total carbon dioxide emissions.

Though burning eFuels will release CO2 in a identical fashion to fossil fuels, synthetic fuels burn cleaner. As opposed to conventional fossil fuels, which have among 30 and 40 factors, synthetic fuels have as several as 8.

Their manufacturing method also captures carbon dioxide originally from the setting, supporting to offset any emissions. Whole emissions are shut to net-zero.

Additionally, artificial gasoline can theoretically be refined to have the very same properties as diesel or petrol accessible now.

This means existing refuelling infrastructure these kinds of common petrol stations and tankers could continue on to be employed, supplying sizeable price financial savings.

Owning the exact same houses as conventionally-sourced fossil fuel also indicates combustion-engined motor vehicles sold today must be equipped to at some point run on eFuel devoid of modification, extending their lifespan.

This could be specifically beneficial in producing markets that if not wouldn’t be able spend for an highly-priced EV charging network.

Now, there also keep on being drawbacks with the eFuel manufacturing method. Although the standard scientific principles are effectively-comprehended, carbon capture and synthesis systems are at a nascent stage of growth, with comparatively big quantities of energy required to accomplish these procedures.

Also, ensuring only renewable vitality is applied to energy the electrolysis course of action stays a obstacle, as this can usually restrict the location or travel up the cost of the eFuel close product or service.

Porsche notes that when eFuel creation has ramped up and economies of scale are realized, it is targeting a wholesale price of $US2.00 for each litre, equivalent to $2.88 a litre (AUD) based mostly on latest exchange fees.

This remains appreciably much more high-priced than even 98 octane premium unleaded out there nowadays, currently being the cost in advance of taxes and other levies.

There is every possibility that eFuel will be commercially offered in a variety of octane scores a great deal like typical and quality unleaded, and any substantial octane eFuel varieties would, of program, carry a bigger expense.

What car organizations are investing in eFuel and is there any neighborhood involvement?

Arguably the most higher-profile automobile enterprise that has created a sizeable determination to eFuel is Porsche.

A short while ago the enterprise introduced it was making a $US75 million financial commitment in HIF World LLC, a holding business that develops, or invests in the advancement of, industrial eFuel production facilities, in return for 12.5 percent ownership of the company.

Porsche claims that this tranche of supplemental funding provides its overall motivation to eFuels to more than $US100 million.

HIF World-wide LLC is, in switch, building eFuel output facilities all around the globe, which include in Punta Arenas, Chile, the place wind ability is envisioned to be a main supply of strength for the electrolysis system.

A lot more: Tasmania to make eco-helpful eFuel for Porsche from 2026

More interestingly, nevertheless, is that HIF World-wide LLC has also fully commited to the improvement of an Australian eFuel manufacturing facility in Burnie, Tasmania.

With design envisioned to start in 2024, HIF expects the plant to begin eFuel production by mid-2026. Greatest envisioned output capability is 190 tons of eFuel per day, or 100 million litres per yr.

For this plant, HIF notes carbon dioxide will be sourced from biogenic (organic and natural) resources, with electric power also currently being sourced from renewable sources.

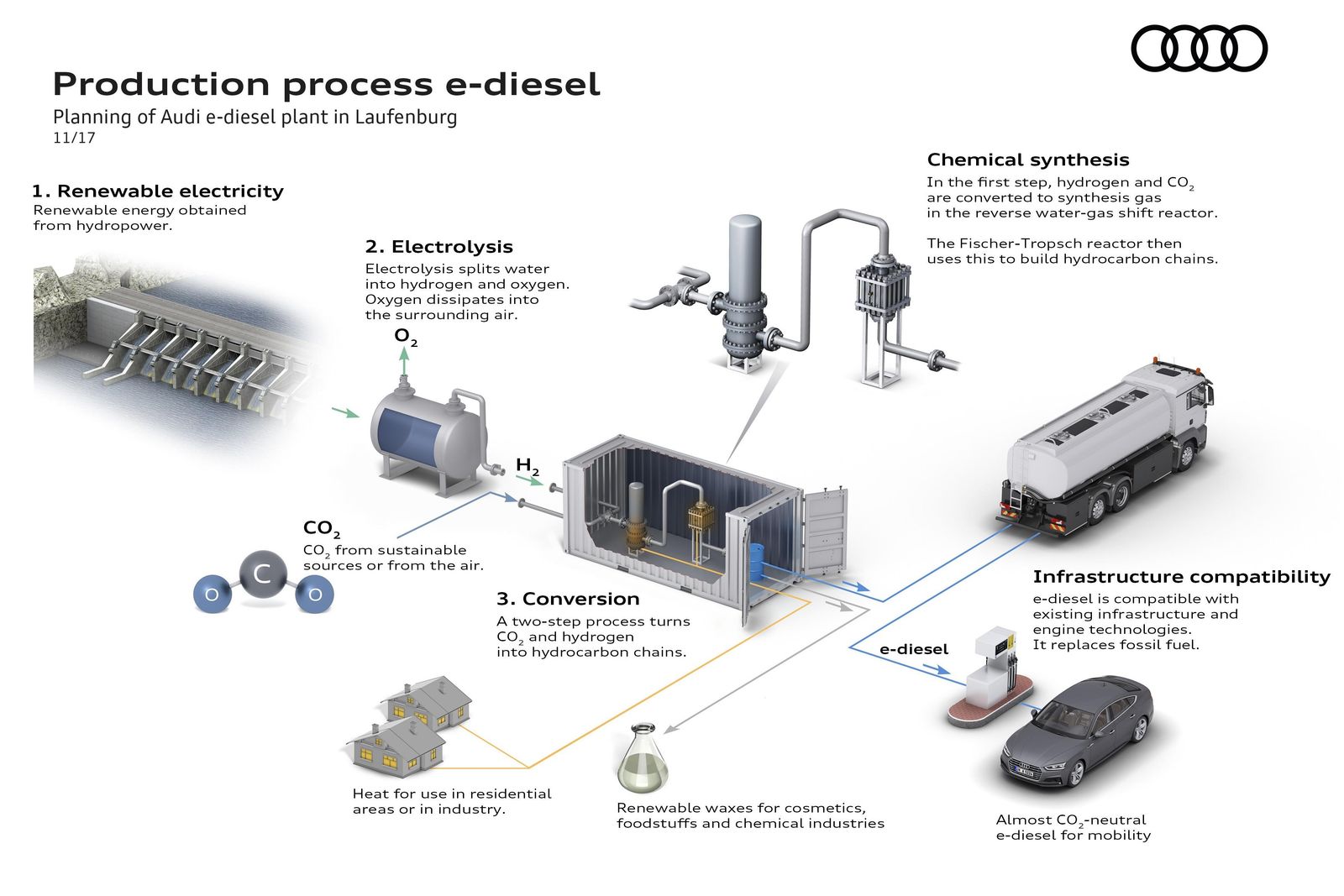

Volkswagen Team stablemate Audi has also shown curiosity in eFuels, and in a 2018 press launch claimed to be arranging a pilot plant for the production of e-diesel, that would be ready to produce 400,000 litres for every calendar year.

More lately, nonetheless, Audi has fully commited to phasing out combustion engines by 2026, and it is unclear to what extent the enterprise will continue to devote in artificial fuels.

Timing and industrial availability

With significant efforts nevertheless becoming built to improve the efficiency of the eFuel creation system, and manufacturing services nonetheless staying rolled out, it is unlikely that eFuels will have popular business availability right until the late 2020s.

When eFuels do turn out to be commercially offered, however, they are envisioned to be appropriate with almost all current petrol and diesel powered motor vehicles.

Additional: Which motor oil should really you use?

Extra: How to maximise electric auto battery longevity

Much more: Filling it up, biodiesel and other biofuels

Extra: Fuel ratings discussed 91, 95, 98 RON and E10