West Surrey Racing may not be a name well known to those who don’t follow the British Touring Car Championship, but their reputation is one that precedes them. While WSR has cut its teeth in the close-knit racing of British Touring Cars for well over two decades, their story stretches back a lot further than that.

West Surrey Racing (WSR) was originally created in 1981 by Dick Bennetts under the umbrella of West Surrey Engineering to compete in the British Formula 3 championship. The precedent for future success was well and truly established when Jonathan Palmer won on the car’s debut, along with securing the championship title that year. Since then, WSR has been instrumental in success for many notable drivers who went on to race (and win) in Formula 1. The aforementioned Jonathan Palmer along with Ayrton Senna, Mauricio Gugelmin, Mika Häkkinen, Reubens Barrichello and Nigel Mansell all spent time in cars run by WSR.

As seems to be commonplace for motorsport-based companies, the outside of the building is fairly understated in comparison to what goes on behind closed doors.

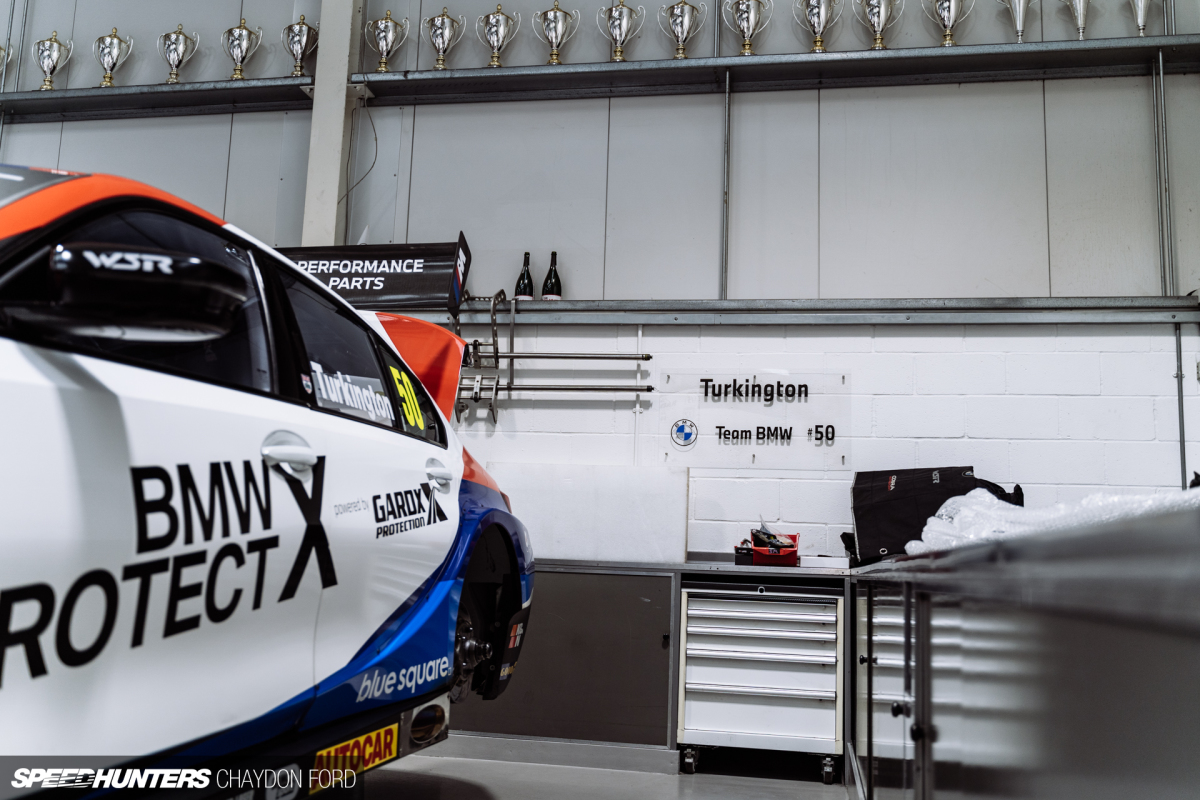

Making your way through the entrance, the first signs of this success are evident. Trophies line the wall from floor to ceiling behind the very F3 car – now sympathetically restored – that took Jonathan Palmer to the drivers championship.

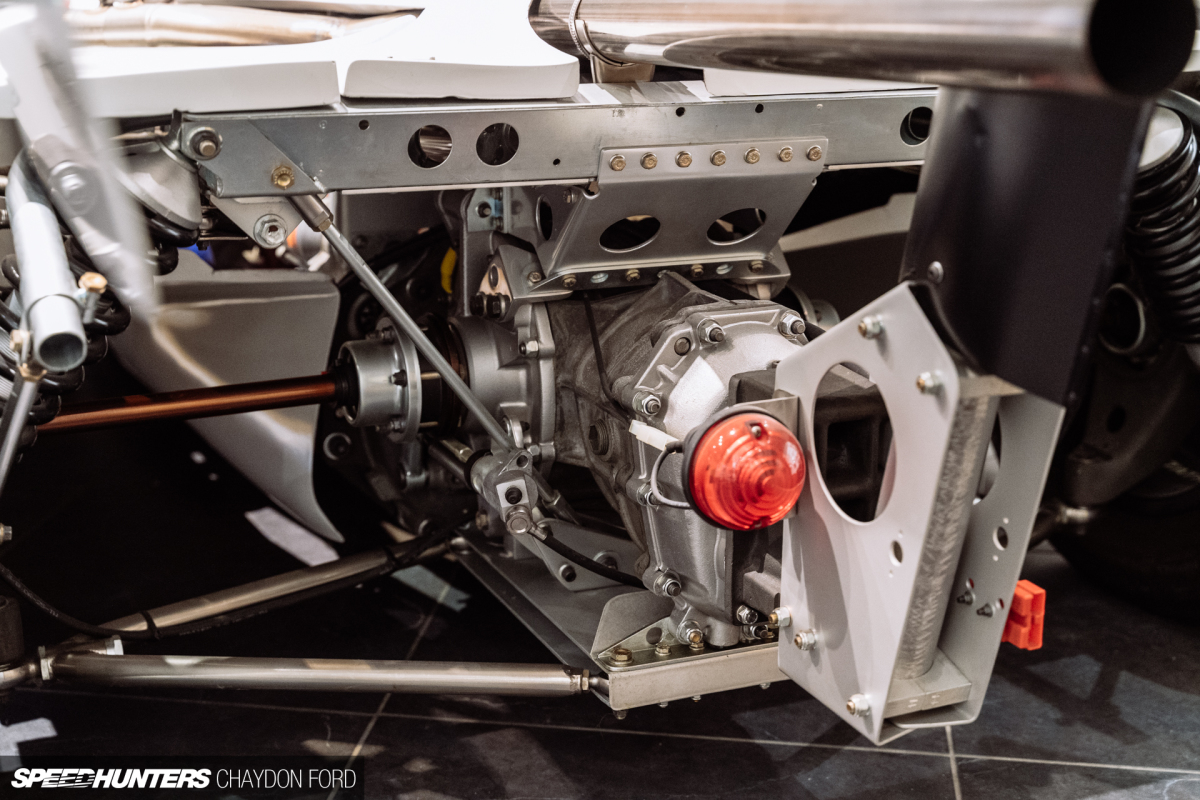

The sub-assembly room next door is designated for gearbox, engine, suspension and damper work. While these components form part of the regulated list, WSR have damper dynamometers and engine/gearbox building facilities in order to fine tune their setups for each respective circuit.

Walking into the vast expanse of the main workshop, the three current BTCC cars are the first you see. WSR design, build and campaign three cars, two under the Team BMW banner and one under Rokit MB Motorsport’s. Further to this, WSR have designed and built two identical customer cars for Ciceley Motorsport.

Each of the three cars had their own bay, with ample work surfaces for whatever job is required. You’ll also note the absence of car lifts, bar one. There is a very good reason for this – the WSR mechanics need to be comfortable working on the car in the same way at all times, be it trackside or at the workshop.

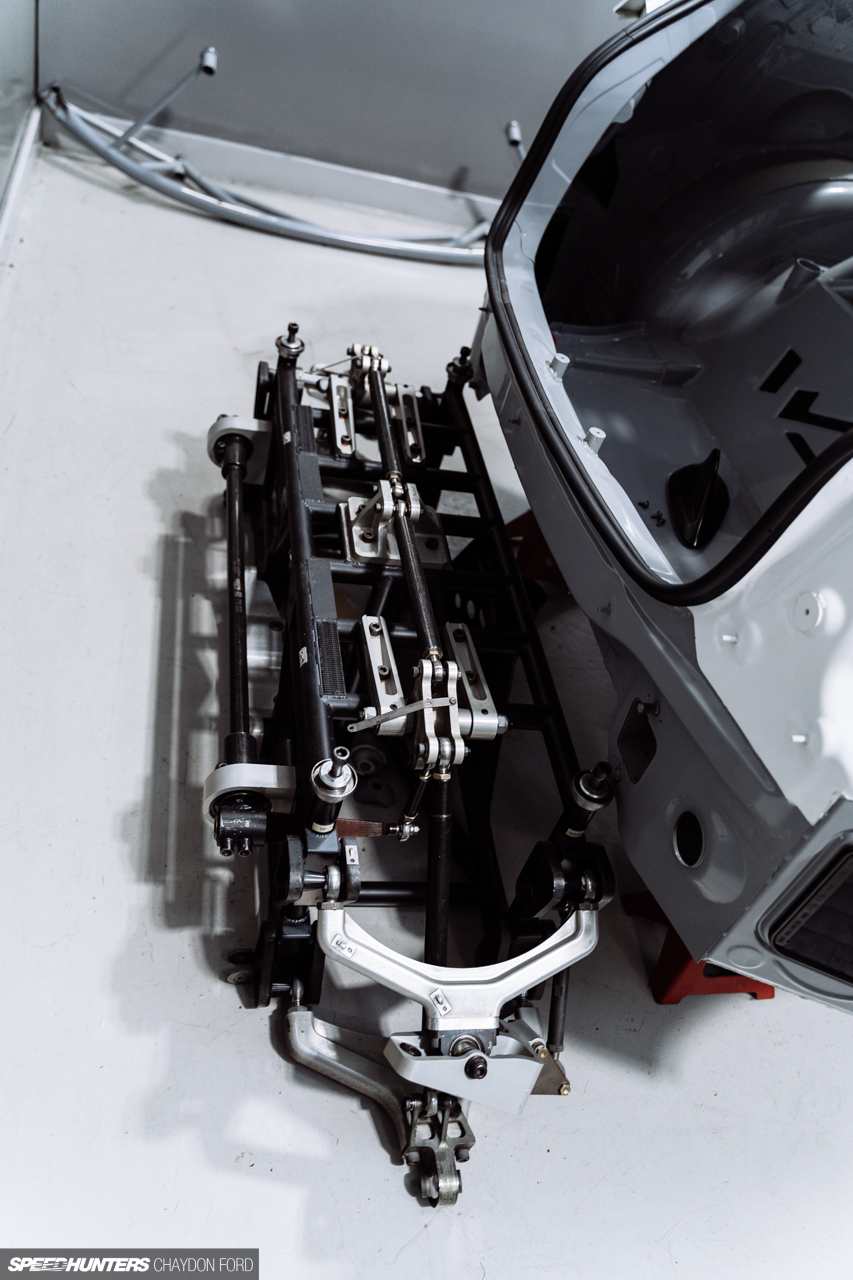

Alongside the three current cars were a few more in various stages of work. The first was a BMW 1 Series hatchback of the body shape WSR campaigned between 2013 and 2018 before reverting back to the more traditional sedan. This shell was a spare that was thankfully never needed.

The exposed nature of the body shell gives an idea of what chassis-specific items fall under the remit of shared components regulated by TOCA. While this car will ultimately be built up and sold on to race in a series other than the BTCC, it gives a good indication of what the team refer to as ’24 hour ready.’ Should a structurally-severe crash occur, a shell in this state could be built back up to a complete running car within one full day.

Next to this sat Colin Turkington’s 2021 BMW 330i, in which he won the 2019 BTCC championship. This car was in the process of being built up once again, after which point it will take its place in a private collection.

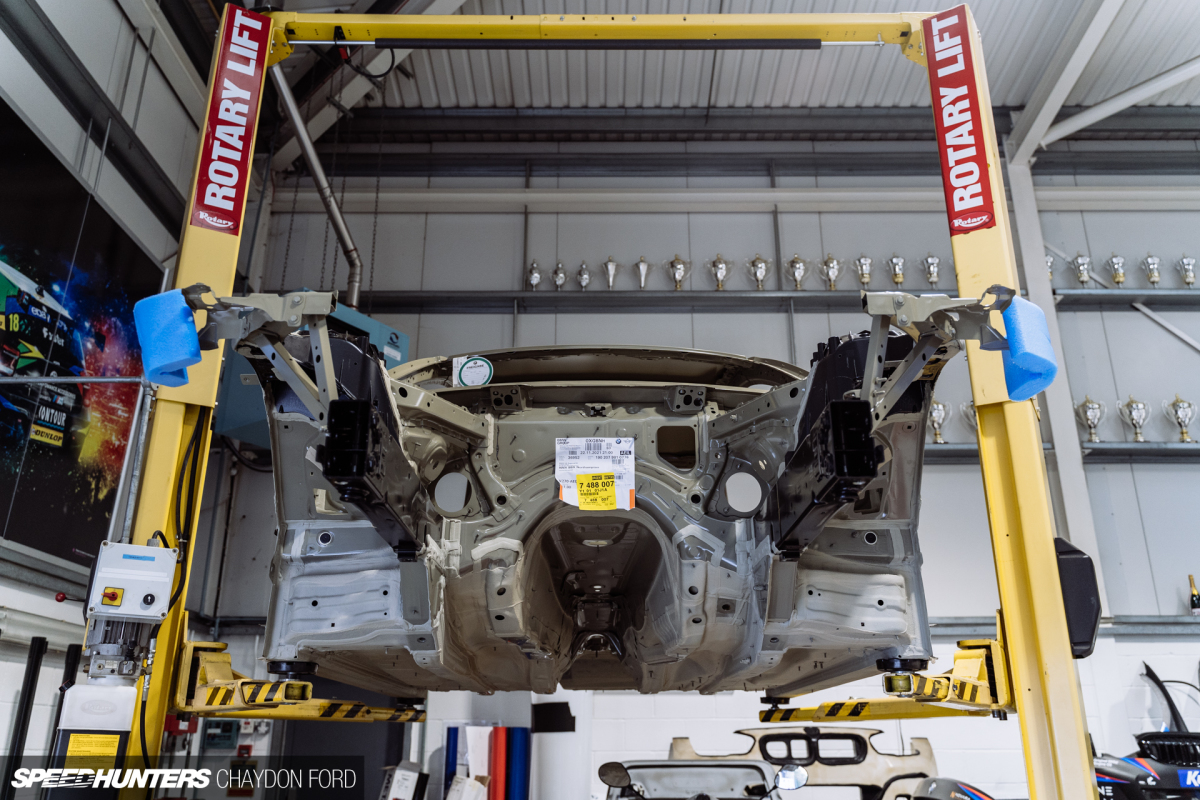

This shell is what the race cars start out as, pulled from the assembly line before any major assembly takes place.

Following an outing for the first test date of the season a day prior, a race truck was parked inside, having just had a car unloaded. With two trucks for three cars, these not only function as car transporters but also mobile workshops, the break room and team command centre over the course of a race weekend. Drawer upon drawer of every conceivable spare part which may be needed fill either side of the centre aisle, along with external lockers for larger items.

And then there’s the tyres – copious amounts of tyres. Goodyear supplies the series with varying compounds as the control tyre, and the WSR team took a large supply along to test ahead of the competitive season.

The ‘patch’, as it is affectionately known, sits in its own dedicated room underneath the large mezzanine. This 15m2 solid steel piece weighs in at at over 10 tonnes and has been set to be perfectly level. Its purpose is to ensure suspension and chassis setup is completely accurate, as well as to diagnose any differences in a chassis following an impact. To get the cars onto the patch, the team uses a forklift with extremely long forks.

If the entrance display did not allude to the victorious nature of West Surrey Racing, the vast expanse of the workshop wall certainly does. Dozens upon dozens of trophies, three tiers tall line the back wall. Carl – the team manager – joked that these are the leftovers after drivers and manufacturers had taken their pick. These trophies are the fruits of labour from the 15 outright championship titles, nine independents’ crowns and over 100 race victories campaigning BTCC programmes for BMW, MG, Honda and Ford.

As my time at WSR drew to a close, the building was eerily quiet with most of the team having left by this point. Seeing the cars sat in silence was in complete contrast to the frenetic and close racing the cars experience over a BTCC race weekend.

If my brief insight into the inner workings were anything to go by, WSR are going to be a force to be reckoned with this season. In a follow up feature, I’ll delve more into the 2022 BTCC BMW 330e and how hybridisation has evolved the series.

Chaydon Ford

Instagram: chaycore